OEM & ODM PCBA, PCB Board Assembly for Electronics Products

Basic Info

| Model NO. | KL 213 |

| Base Material | Aluminum |

| Insulation Materials | Organic Resin |

| Model | PCB |

| Brand | Customer′s Brand |

| Surface Treatment | Gold Finger/Hard Gold |

| Layers | 1-36layers |

| Board Thickness | 0.2-6mm |

| Copper Thickness | 0.5-12oz(18-420um) |

| Solder Mask Color | Green/Black/White/Red/Blue/Yellow |

| Hole Diameter | Min0.05mm |

| Min. Line Width | 0.10mm(4mil) |

| Min. Line Spacing | 0.10mm(4mil) |

| Test | 100% E-Test |

| One Stop Service | PCB Assembly, Component Sourcing, Box Building |

| Max. Finished Board Side | 1020mm*1000mm |

| MOQ | No |

| Sample Date | 5-7days |

| Certification | RoHS, UL, ISO |

| Shipment | Air,Sea,Express(DHL TNT FedEx EMS UPS) |

| Transport Package | Customized, ESD Bag/Vacuum Packaging+Bubble Bag, |

| Specification | 49 x 42 x 36 Centimeters/Piece |

| Trademark | JXpcba |

| Origin | China |

| HS Code | 9006599030 |

| Production Capacity | 50000000pieces/Year |

Product Description

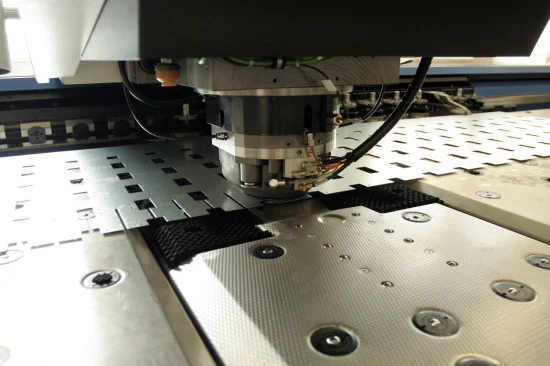

... Shenzhen Jingxin Electronic Technology. ... Built since 2002, is a almost 20 years professional company dedicating to PCB&PCBA industry. Our factory located in Shenzhen, and have dust-free workshop which cover an area of over than 10000m², almost 550 employees, more than 30 production lines include SMT,DIP,automatic welding,aging test and assembly. We have equipments of over 50 SMT machines from Japan and Korea, automatic solder paste printing machines, solder paste inspection machine(SPI), 12 temperature zone reflow soldering machine, AOI detector, X-RAY detector, wave soldering machine, EM PCB dispenser, laser print machine etc., Different line configurations can meet requirements from small sample order to bulk shipment. Our company has obtained ISO 9001 quality system certification and ISO 14001 system certification. With multi-testing procedures, our products carry out the quality system standard strictly. With end to end one-stop manufacturing solution, the company has become a benchmarking enterprise in the industry, and has been earning industry praises and good reputation from domestic and international customers depending on rigorous, techniques, good quality, fast delivery and excellent service.

... factory ...... Equipment ...

... strength ...

... products ...

... Specification ...

| Term | Detailed Specification of PCBA Board Manufacturing |

| Layer | 1-30 layer |

| Material | FR-4, CEM-1, CEM-3, Hight TG, FR4 Halogen Free, FR-1, FR-2, Aluminum |

| Board thickness | 0.4mm-4mm |

| Max.finished board side | 1020mm*1000mm |

| Min.drilled hole size | 0.25mm |

| Min.line width | 0.10mm(4mil) |

| Min.line spaceing | 0.10mm(4mil) |

| Surface finish/treatment | HASL/HASL lead free,Chemical tin,Chemical Gold,Immersion gold Inmersion Silver/Gold,Osp,Gold Plating |

| Copper thickness | 1/2OZ 1OZ 2OZ 3OZ |

| Solder mask color | green/black/white/red/blue/yellow |

| Inner packing | Vacuum packing,Plastic bag |

| Outer packing | Standard carton packing |

| Hole tolerance | PTH:±0.076,NTPH:±0.05 |

| Certificate | ISO9001,ISO14001,ROHS,CQC |

| Profiling Punching | Routing,V-CUT, Beveling |

| Assembly Service | Providing OEM service to all sorts of printed circuit board assembly |

| Technical Requirement | Professional Surface-mounting and Through-hole soldering Technology |

| Various sizes like 1206,0805,0603 components SMT technology | |

| ICT(In Circuit Test),FCT(Functional Circuit Test) technology | |

| PCBA Assembly With CE,FCC,Rohs Approval | |

| Nitrogen gas reflow soldering technology for SMT | |

| High Standard SMT&Solder Assembly Line | |

| High density interconnected board placement technology capacity | |

| Quote&Production Requirement | Gerber File or PCBA File for Bare PCBA Board Fabrication |

| Bom(Bill of Material) for Assembly,PNP(Pick and Place file) and Components Position also needed in assembly | |

| To reduce the quote time, please provide us the full part number for each components,Quantity per board also the quantity for orders. | |

| Testing Guide&Function Testing method to ensure the quality to reach nearly 0% scrap rate | |

| OEM/ODM/EMS Services | PCBA, PCBAAassembly: SMT & PTH & BGA |

| PCBA and enclosure design | |

| Components sourcing and purchasing | |

| Quick prototyping | |

| Plastic injection molding | |

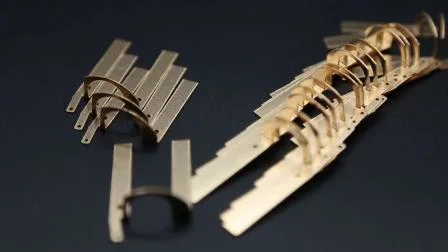

| Metal sheet stamping | |

| Final assembly | |

| Test: AOI, In-Circuit Test (ICT), Functional Test (FCT) | |

| Custom clearance for material importing and product exporting | |

| Other PCBA Assembly Equipment | SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4 |

| Reflow Oven: FolunGwin FL-RX860 | |

| Wave Soldering Machine: FolunGwin ADS300 | |

| Automated Optical Inspection (AOI): Aleader ALD-H-350B,X-RAY Testing Service | |

| Fully Automatic SMT Stencil Printer: FolunGwin Win-5 |

... certification ...

... exhibition ...... Packing and shippment ...

... FAQ ...

Q1.What is needed for quotation?

A: PCB : Quantity, Gerber file and Technic requirements(material,surface finish treatment, copper thickness,board thickness ,...)PCBA: PCB information, BOM, (Testing documents...)

Q2. What file formats do you accept for production?

A: Gerber file: CAM350 RS274XPCB file: Protel 99SE, P-CAD 2001 PCBBOM: Excel (PDF,word,txt)

Q3. Are my files safe?

A: Your files are held in complete safety and security.We protect the intellectual property for our customers in the whole process.. All documents from customers are never shared with any third parties.

Q4. MOQ?

A: There is no MOQ in JXE PCBA. We are able to handle Small as well as large volume production with flexibility.

Q5.Shipping cost?

A: The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the shipping cost.

Q6. Do you accept process materials supplied by clients?

A Yes, we can provide component source, and we also accept component from client.

One-Stop OEM PCB Assembly Professional Turnkey PCBA