Agni Electrical Contact Rivets

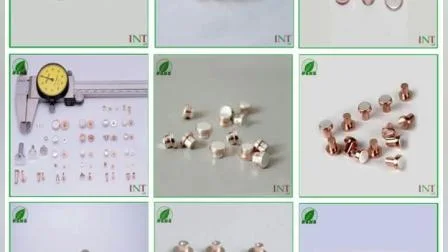

AgNi Electrical Contact rivets Electrical contacts factory, more than 12 years manufacture experience, attained ISO9001-;

Basic Info

| Model NO. | ER19 |

| Transport Package | Carton Box |

| Specification | according to drawing |

| Trademark | INT |

| Origin | China |

| HS Code | 8538900000 |

| Production Capacity | 5000000/Month |

Product Description

AgNi Electrical Contact rivetsElectrical contacts factory, more than 12 years manufacture experience, attained ISO9001-2015, work on OEM and ODM projects..

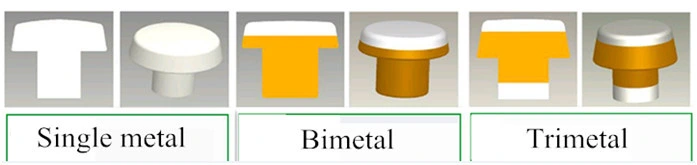

1. Introduction of Silver nickel electrical contact

Silver nickel AgNi electrical contact has a high level of electrical and thermal conductivity, good plasticity and arc corrosion resistance, as well as a very low contact resistance.

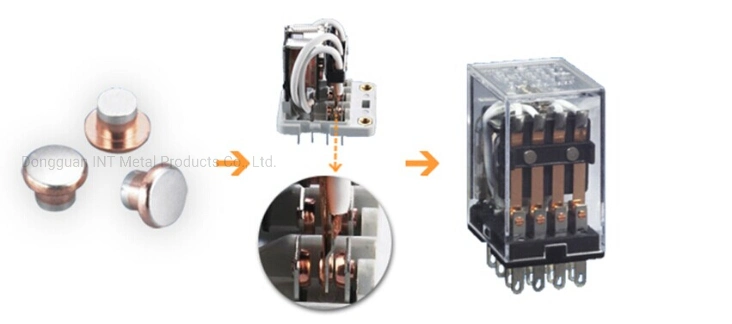

2. Application of Silver nickel electrical contact

Mainly used in all kinds of switch, controller, voltage regulator, circuit breaker, automotive electrical, magnetic starter, and so on. Normally suit for the electric current which below 100A, AgNi10 is commonly used to the AC contactor below 20A, AgNi (15 ~ 40) are able to bear a larger electric load.

3. Main Materials for Silver nickel electrical contactAgNi10, AgNi12, AgNi15, AgNi20, AgNi30

| Category | Density g/cm3≥ | Electrical conductivity .cm≤ | Hardness soft HV≥ | Tensile strength soft MPa≥ |

| AgNi10 | 10~10.32 | 2.10 | 75 | 310 |

| AgNi12 | 10~10.32 | 2.1 | 75 | |

| AgNi15 | 9.9~10.23 | 2.2 | 76 | 320 |

| AgNi20 | 9.8~10.15 | 2.3 | 77 | 320 |

| AgNi30 | 9.7~9.97 | 2.7 | 80 |

4.Specification of the Silver nickel electrical contact

Dimensions can be customized

| Contact rivet dimension and tolerance | |||||||

| Item | Head Diameter D(mm) | Head Thickness T(mm) | Layer Thickness S(mm) | Shank Diameter d(mm) | Shank Length L(mm) | Sphere Radian R(mm) | Mold Ratio θ |

| Specification | 2.5 | 0.6-1 | 0.3-0.4 | 1.2-1.5 | 1-2 | 4-6 | 9 |

| 3 | 0.8-1.2 | 0.3-0.5 | 1.5 | 6-8 | |||

| 3.5 | 1.5-2.0 | 1-3 | |||||

| 4 | 1.0-1.5 | 2 | 8-10 | ||||

| 4.5 | 2.0-2.5 | ||||||

| 5 | 1.0-2.0 | 0.4-0.6 | 2.5 | 10-15 | |||

| 5.5 | 2.5-3.0 | ||||||

| 6 | 3 | 15-20 | |||||

| 6.5 | 1.2-2.0 | 0.5-0.7 | 3.0-3.5 | ||||

| 7 | 3.5 | 20-25 | |||||

| 8 | 4 | ||||||

| Tolerance | ±0.1 | ±0.05 | ±0.05 | ±0.05 | ±0.15 | ±0.2 | ±2 |

6. Manufacture plant of Silver nickel electrical contact

7. Mill certificate for Silver nickel electrical contact

8. Packing and shipping for Silver nickel electrical contact

Packing:

First put 500-5000 pcs into small plastic bags or vacuum plastic bags, then in separated small carton box, at last Into hard cardboard box.

Shipping:

We will choose the best way according to customer's requests.1. By Air, to the indicated airport.

2. By Express (FedEx, UPS, DHL, TNT, EMS), to the indicated address.2. By Sea, to the indicated sea port.

9.FAQ

1. Do you have ISO certificate?

Yes, we obtained ISO9001

2. How long is your delivery time for electrical contacts?

15-25 days depend on the raw material condition

3. Do you make parts according to our design?

Yes, we always do as per customers drawings or Technical documents

4. Can you help us to choose suitable material?

Yes, we can recommend the most suitable material according to your application.

5. Do you provide sample? Free or charge?

Yes, if the sample in stock available, free of charge, if not, need to charge some mfg cost.

You may also like

Send inquiry

Send now